When it comes to energy-saving strategies, the sky’s the limit, especially in countries like India, Bangladesh, Kenya, Uganda, Nigeria, UAE. Consider other energy-efficient options such as adding insulation to equipment, investing in double-paned windows, or using energy-efficient frying systems. You can even invest in renewable energy sources like wind power or geothermal energy.

It all comes down to understanding your energy needs and finding ways to reduce or eliminate wasteful consumption of resources in your chips-making factory. To measure your progress, remember to keep track of your energy usage and green initiatives over a period of time. By tracking your progress, you’ll be able to identify areas of improvement and take steps to increase your energy efficiency.

When producing potato chips through a fully automatic potato chips line, maintaining the right level of heat is essential to energy efficiency. To achieve optimal energy savings, look no further than managing your heat levels efficiently. Here are some recommendations to begin with:

When it comes to producing delicious potato chips, energy efficiency is key. It might seem like the process is mostly automated, but there are some simple steps you can take to reduce the amount of energy needed when manufacturing chips.

Next, make sure to look into alternative sources of energy such as solar power or wind turbines if they are available in your area. This will significantly reduce costs while you’re producing potato chips and help reduce environmental impact.

By following these tips, you can ensure that your potato chip production process is both environmentally friendly and cost-effective!

Modern technology is key when it comes to saving energy in potato chip production. Not only does it increase overall efficiency, but it helps reduce energy costs as well! Here are some of the top ways you can use modern technology to save energy:

Adding motion sensors to your potato chips machine is also a great way to reduce wasted energy. These sensors detect motion and will turn off the equipment when it is not being used – making sure that you don’t have any unnecessary power usage while the machines are idle.

A digital monitoring system helps you keep track of all the processes in your potato chip production, allowing you to make more informed decisions about how much energy you’re using. That way, you’ll know when and where adjustments need to be made in order to maximize efficiency while minimizing output costs.

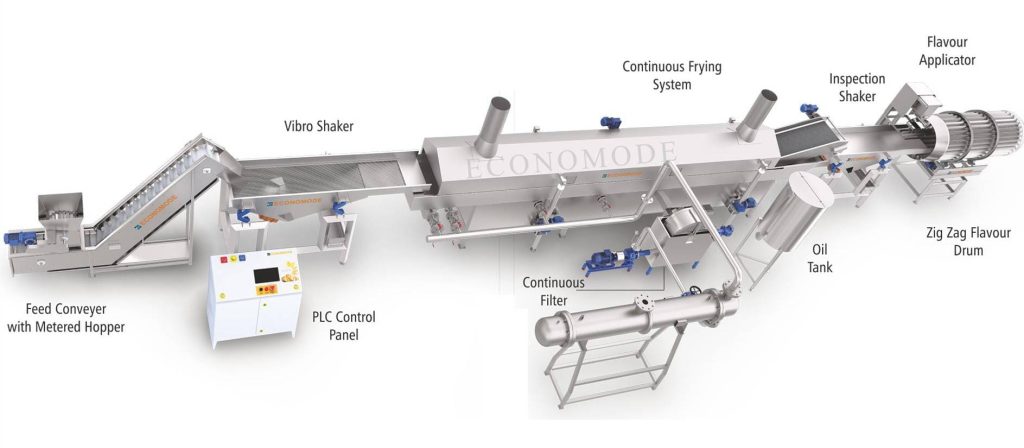

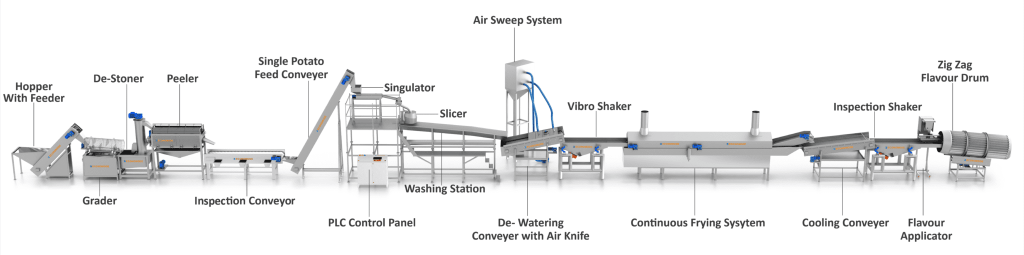

Invest in Energy Saving Machines

You may not know this, but investing in energy-efficient machines can save you a great deal of money and energy in the long run! The right potato chips making line can help reduce energy costs, decrease waste and increase productivity—which all add up to a healthier bottom line.

So why is investing in energy-saving potato chips machine so important

Modern potato chip production processes are highly automated, which means electricity or other forms of energy are used to operate the machines. Investing in newer, high-efficiency machines can greatly reduce your overall energy consumption.

Energy-efficient potato chip production machines generally require less human supervision than older models, freeing up workers for more meaningful tasks. This increases productivity while ensuring that quality remains high and consistent across the board.

These days, there are plenty of eco-friendly options available—so why not give them a try? Investing in Economode’s energy-saving fully automatic potato chips line could be one of the best decisions your business ever makes!

If you want to save energy when producing potato chips, you need to make sure you are maximizing production with the lowest power consumption rate. To make this happen, here are a few tips that can help you out.

You can also implement energy-efficient strategies such as using LED lighting, setting heating/cooling systems at specific temperatures or using energy-efficient motors and pumps in order to reduce energy consumption. These small changes can really add up over time!

Finally, consider using renewable energy sources like solar power to produce your potato chips. Solar power is clean, sustainable and cost-effective – plus it’s much more environmentally friendly than traditional sources of power!

Potato chip production does require energy, but there are steps you can take to minimize waste and maximize your efficiency. From using the right potato chips making line in India, Bangladesh, Kenya, Uganda, Nigeria, UAE to utilizing any other available energy-saving technologies, it’s possible to produce potato chips with minimal energy consumption. Start implementing these tips today and watch your Potato chips manufacturing unit grow